Special Purpose Transformers

Special Purpose Transformers Specification

- Operating Temperature

- -25C to +50C

- Load Loss

- Low loss, as per IEC Standards

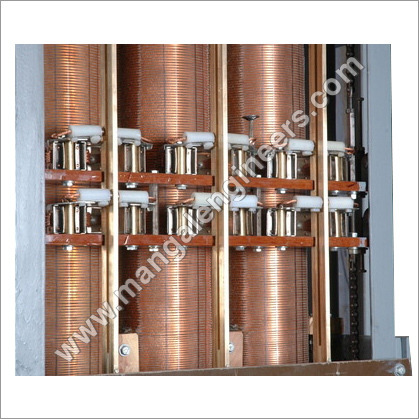

- Coil Material

- Electrolytic Copper

- Dimension (L*W*H)

- As per design

- Cooling Type

- Oil Cooled / Air Cooled

- Voltage Booster Type

- Step Up / Step Down / Isolation

- Low Voltage

- 415 V / 690 V (Customizable)

- High Voltage

- 5 kV to 33 kV

- Rated Voltage

- Up to 33 kV

- Capacity

- Up to 5000 kVA

- Product Type

- Special Purpose Transformer

- Material

- Copper & Silicon Steel

- Output

- Custom Output

- Frequency (MHz)

- 50 Hz

- Efficiency

- Up to 98%

- Phase

- Three Phase

- Usage

- Industrial and commercial electrical systems

- Coil Structure

- Toroidal & Laminated Core

- Coil Number

- Double Coil

- Power Scope

- Custom Range

- Weight

- As per specification

About Special Purpose Transformers

From our extensive range of products, we manufacture, export and supply supreme quality Special Purpose Transformers. For the manufacturing of these transformers, our professionals use premium grade raw material and pioneering technology in sync with the defined international quality standards. Offered transformers are used as set up transformer from generator to line voltage. These Special Purpose Transformers are available in varied capacities as per the application requirements of customers at reasonable rates.

Key Features:

- Long service life

- High operational fluency

- Heat and shock resistance structure

- Low energy consumption

Versatile Customization and Superior Design

Our special purpose transformers can be tailored with various mounting types, enclosures, and input/output voltages to meet diverse industrial or commercial needs. With advanced coil structures, high-quality core materials like CRGO or amorphous, and customizable output ranges, you receive a transformer that fits your exact application. Epoxy-coated, weather-resistant finishes protect against harsh environments for long-lasting service.

Stringent Standards and Reliable Testing

Compliant with IS 2026 and IEC 60076, each unit undergoes routine, type, and special tests. This rigorous approach guarantees safety, low noise, and high efficiency. Whether for step-up, step-down, or isolation applications, transformers are engineered to minimize load losses and operate efficiently, ensuring consistent power delivery even in demanding conditions.

FAQs of Special Purpose Transformers:

Q: How are special purpose transformers customized to meet specific power requirements?

A: Our transformers are designed according to client specifications, including rated voltage (up to 33 kV), capacity (up to 5000 kVA), impedance voltage (3.5%12%), and output configurations. Options for core material, coil structure, mounting, and enclosure allow complete customization for each project.Q: What testing standards do these transformers comply with during the manufacturing process?

A: All units are manufactured and tested in accordance with IS 2026 and IEC 60076 standards. They undergo routine, type, and special tests to ensure performance, efficiency, and safety for industrial and commercial applications.Q: When should an off-circuit or on-load tap changer be used?

A: Use an off-circuit tap changer when voltage adjustments are infrequent and power can be interrupted, or an on-load tap changer when voltage regulation is needed without disrupting the supply. Selection depends on the operational requirements of your system.Q: Where can these transformers be installed and what are their mounting options?

A: Transformers are suitable for both indoor and outdoor installations, featuring robust enclosures for protection. Mounting options include floor-mounted or skid-mounted bases, allowing flexible deployment in various environments.Q: What benefits do epoxy coated and weather-resistant finishes provide?

A: Epoxy coatings offer excellent resistance to moisture, chemicals, and weather, ensuring durability in tough industrial or outdoor environments. This enhances the lifespan and reliability of the transformer.Q: How does the transformer maintain high efficiency and low load loss?

A: By utilizing advanced core materials like CRGO or amorphous steel and precise manufacturing as per IEC standards, these transformers achieve efficiency up to 98% and maintain low load losses, optimizing energy use and reducing operational costs.Q: How are these transformers typically used in industrial and commercial systems?

A: They are used for voltage regulation (step-up/step-down), isolation, and reliable power distribution within complex electrical systems for factories, utilities, and large commercial facilities, offering safe and efficient conversion and management of electrical energy.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electrical Transformers Category

Earthing Transformers

Price Range 10000.00 - 10000.00 INR / Set

Minimum Order Quantity : 1 Set

Usage : Earthing for neutral grounding in distribution networks and power substations

Rated Voltage : 6.6 kV 33 kV

Product Type : Other, Earthing Transformer

Variable Transformers

Price Range 10000.00 - 100000.00 INR / Set

Minimum Order Quantity : 1 Piece

Usage : Voltage regulation, laboratory testing, industrial equipment, educational training

Rated Voltage : 230 V AC input (standard), others on request

Product Type : Other, Manual Variable Transformer (Variac)

Current Balancing Transformers

Price Range 10000.00 - 100000.00 INR / Set

Minimum Order Quantity : 1 Set

Usage : For current balancing in electrical circuits and equipment

Rated Voltage : 415 V

Product Type : Other, Current Balancing Transformer

Ultra Isolation Transformers

Price 50000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Rated Voltage : 220440 Volt (V)

Product Type : Isolation Transformer

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS